Impact Bars & Beds

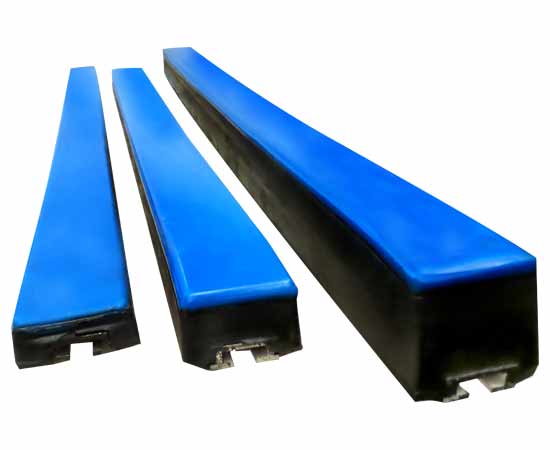

Impact Bars

Impact Bars are used in the materials loading area of a conveyor system to replace the impact idler rollers with the aim of reducing costs.

Maintenance of impact rollers is reduced, belt damage is minimised, whilst belt life is extended. Additionally, shocks transmitted to the conveyor system are reduced.

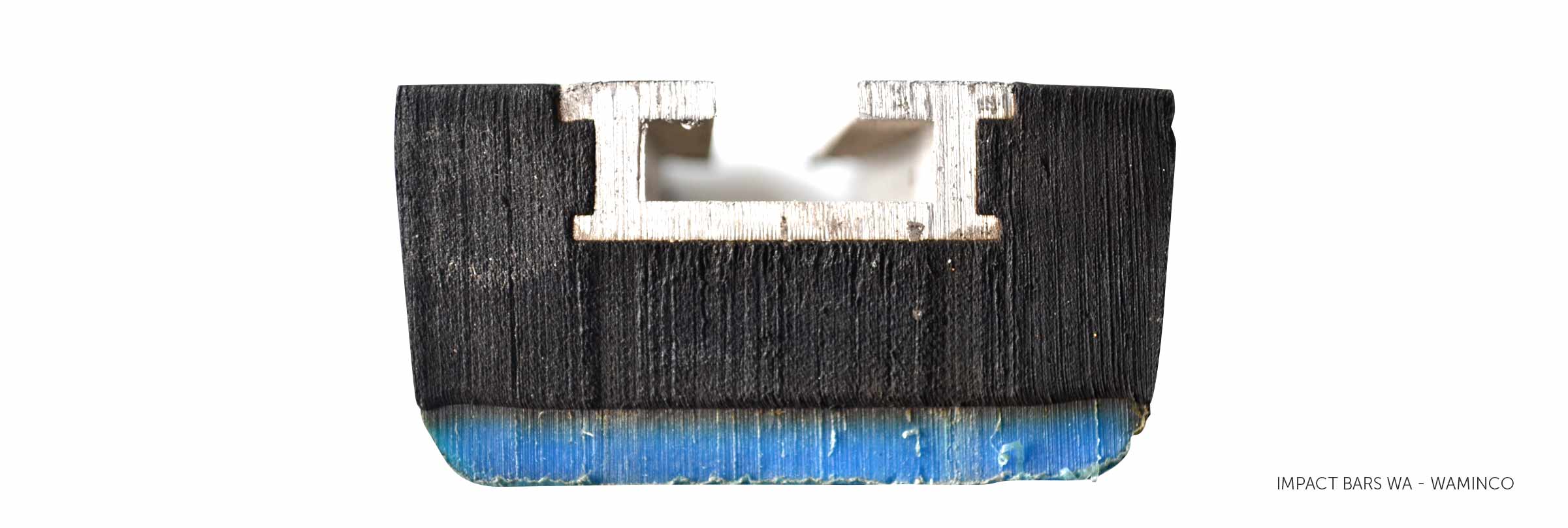

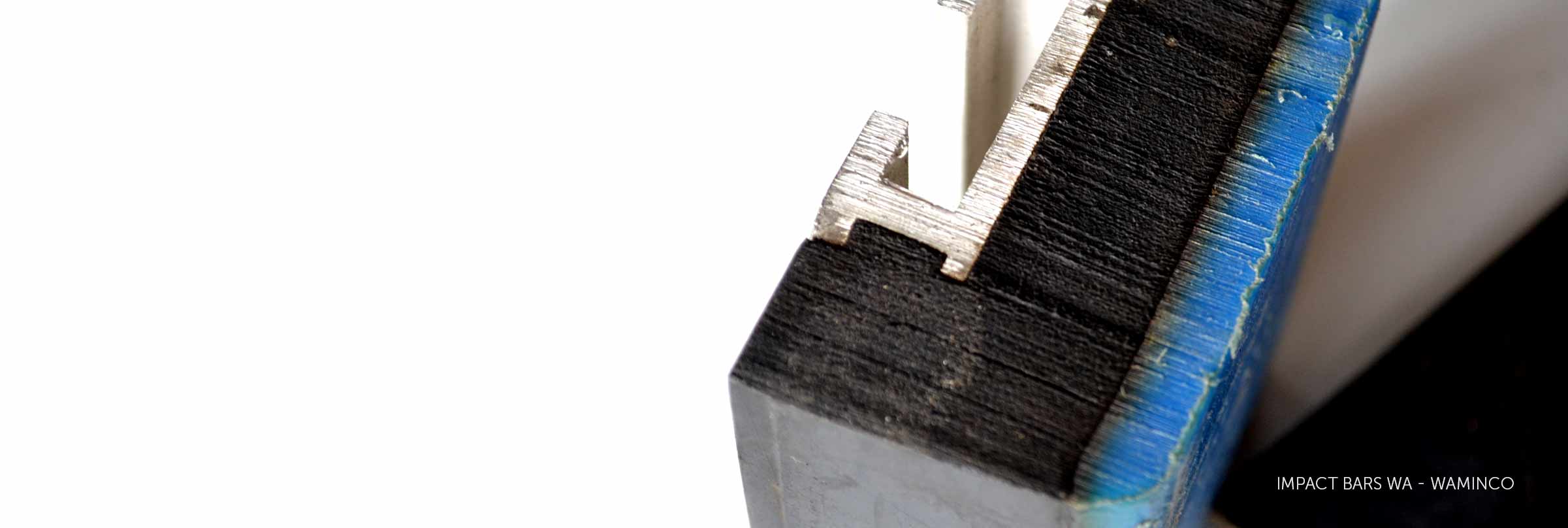

Construction

The top layer consists of highly impact resistant UHMWPE with very low sliding friction.

The base layer is a highly elastic rubber compound to absorb the material impact.

Vulcanised into the rubber base is an aluminium T-Track facilitating the fastening of the impact bar onto the cradle frame at any number or locations.

Size

| Part No. (Without Bolts) | Part No. (With T-Bolts) | Height (mm) | Width (mm) | Length (mm) |

|---|---|---|---|---|

| IBAR-050-1250 | IBAR-050-1250 | 50mm | 100mm | 1250mm |

| IBAR-050-1524 | IBAR-050-1524-5TB | 50mm | 100mm | 1524mm |

| IBAR-050-1800 | IBAR-050-1800-6TB | 50mm | 100mm | 1800mm |

| IBAR-075-1524 | IBAR-075-1524-5TB | 75mm | 100mm | 1524mm |

| IBAR-075-1800 | IBAR-075-1800-6TB | 75mm | 100mm | 1800mm |

Specifications

| UHMWPE Top | |

|---|---|

| Colour | Blue |

| Tensile Strength | 44 N/mm2 |

| Coefficient of Friction | 0.03 |

| Hardness | 63~90° Shore-D |

| Elongation at Break | 50% |

| Rubber Base | |

|---|---|

| Colour | Black |

| Tensile Strength | 15 MPa |

| Hardness | 65° Shore-A |

| Elongation at Break | 500% |

Impact Beds

Impact Beds are available to size and specification.

- Other size bars up to 1800mm long are available.

- Impact bars can be easily cut to shorter lengths as required.

- Impact Bars are supplied with appropriate M16 T-Bolts for mounting the bar to the impact bed.